Streamline Purification of Glycosylated Proteins with Recombinant Prokaryotic Lectins

Glycosylation affects the safety and efficacy of biologic drugs, making it a Critical Quality Attribute (CQA) for biotherapeutic manufacturing. Recombinant prokaryotic lectins (RPLs) provide several advantages for purifying glycosylated biotherapeutics and are applicable to both glycoanalysis and downstream processing.

Drawbacks of traditional glycoprotein purification methods

Traditional chromatographic methods for purifying glycoproteins require independent development for each biotherapeutic target. This can add considerable time and expense to workflows, while the inherent complexity of established approaches makes outcomes difficult to predict.

Advantages of RPLs for glycoprotein purification

Lectins have been widely used for purifying glycoproteins because of their ability to recognise and bind distinct glycans. Compared to conventional, plant-based lectins, RPLs offer superior specificity, consistency, and scalability for more cost-effective glycoprotein purification.

Purification of HIV gp120 envelope glycoproteins with RPL affinity resins

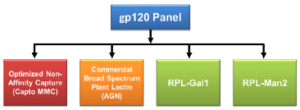

Two RPL affinity resins, RPL-Gal1 (galactose-specific) Sepharose and RPL-Man2 (mannose-specific) Sepharose, were used for purifying a panel of HIV gp120 envelope glycoproteins directly from harvest media. In parallel, two traditional non-affinity based chromatographic matrices were also used.

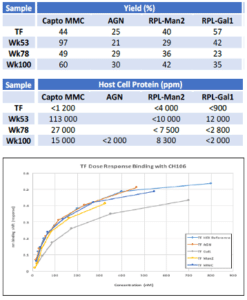

Resin performance was assessed by measuring the product yield and host cell protein (HCP) concentration, while the potency of the isolated product was determined using ELISA to evaluate reactivity with broadly neutralising antibodies such as CH106.

RPL affinity resins were shown to:

- Produce equivalent or better results than non-affinity capture methods

- Deliver Protein A-like affinity clearance of HCPs, without any optimisation

- Be suitable for both R&D and large-scale purification of glycoproteins

- Represent generic tools for isolating a broad range of glycosylated products, reducing the number of polishing steps required post-capture to streamline downstream processing

- Enable optimisation for a specific manufacturing process